Injection Epoxy Chemical Anchors Market Set for Robust Expansion Across APAC, Europe, USA, and Saudi Arabia by 2035

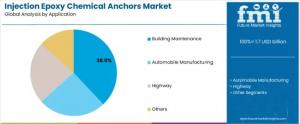

Fast Curing Type will dominate with a 58.0% market share, while building maintenance will lead the application segment with a 38.0% share.

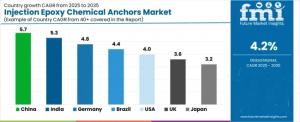

NEWARK, DE, UNITED STATES, November 11, 2025 /EINPresswire.com/ -- The global Injection Epoxy Chemical Anchors Market is entering a decade of strong and sustained growth, driven by surging construction activities, infrastructure rehabilitation, and industrial expansion. The market, valued at USD 1.7 billion in 2025, is projected to reach USD 2.6 billion by 2035, advancing at a compound annual growth rate (CAGR) of 4.2%.

As industries, governments, and developers continue to demand high-performance fastening systems, injection epoxy chemical anchors are emerging as the cornerstone of modern construction and industrial stability. These anchors provide unmatched load-bearing strength, superior bonding on varied substrates, and durability under harsh environmental conditions — essential traits in high-rise, transportation, and energy infrastructure projects worldwide.

Request the complete report to gain a clear understanding of regional growth patterns, innovation trends, and competitive intelligence! Request Sample Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-27972

Market Overview: Anchoring Growth Across Sectors

The next decade promises substantial structural transformation across both developed and emerging economies. Rising global investments in construction and retrofitting — particularly in seismic reinforcement, bridge maintenance, and heavy industrial facilities — are propelling demand for advanced epoxy-based anchoring systems.

In 2025, building maintenance applications account for the largest revenue share, approximately 38 %, followed by highway construction (24 %), automotive manufacturing (19 %), and large-scale infrastructure projects (12 %). Among product categories, fast-curing injection epoxy anchors dominate with about 58 % share, reflecting growing preference for time-efficient, high-performance solutions.

Between 2025 and 2030, the market is expected to grow by approximately USD 238 million, with accelerated momentum anticipated from 2030 to 2035 as rapid urbanization and automation reshape installation techniques. Nearly three-quarters of the decade’s total incremental revenue is forecast to occur in the latter five years as large-scale projects mature.

Regional Dynamics: Four Power Centers of Growth

Asia-Pacific (APAC): Construction Mega-Cycle Drives Demand

Asia-Pacific remains the undisputed leader in volume growth, fueled by rapid urban development, infrastructure modernization, and expanding industrial footprints in countries such as China, India, Japan, and South Korea. Accelerated government spending on highways, metro systems, ports, and smart-city infrastructure is boosting anchor consumption across the region.

Rising focus on safety compliance and load-tested bonding systems in high-rise construction is further propelling market growth. The APAC market is projected to outperform the global average CAGR, reinforcing its position as the world’s fastest-growing regional segment through 2035.

Europe: Sustaining Growth Through Retrofit and Renovation

Europe demonstrates steady demand anchored in renovation, retrofitting, and infrastructure reinforcement. Valued at approximately US $459 million in 2025, the European market is projected to climb to around US $647 million by 2035, registering a CAGR of 3.5 %.

Germany leads the region, commanding close to 30 % market share owing to its robust industrial base and well-established construction sector. Other key markets — including the UK, France, and Italy — are witnessing renewed spending on sustainable buildings, seismic upgrades, and public infrastructure repairs. European manufacturers are emphasizing low-VOC, environmentally compliant epoxy formulations to align with stringent regulatory standards.

United States: Infrastructure Modernization Accelerates Uptake

In the United States, infrastructure renewal has become a cornerstone of economic policy. Major investments in highway bridges, tunnels, and public transportation systems are catalyzing steady growth in demand for structural adhesives and anchors. The U.S. market’s trajectory mirrors its commitment to safety and durability in both private and public sector projects.

Rapid adoption of fast-curing epoxy systems for highway restoration, heavy-equipment anchoring, and green-energy installations — particularly in wind and solar — is boosting consumption. As industrial facilities modernize and manufacturing sites expand, demand from maintenance and repair operations continues to strengthen.

Saudi Arabia and the Middle East: Vision-Driven Infrastructure Boom

Saudi Arabia’s ambitious urban development programs, spearheaded by mega-projects such as smart cities, airport expansions, and transport corridors, are creating extraordinary opportunities for injection epoxy chemical anchors. The market across Saudi Arabia and the broader Middle East is expected to achieve a CAGR exceeding 4.5 % through 2035.

Rising investments in oil-and-gas facility maintenance, power infrastructure, and industrial retrofitting are accelerating adoption. The shift toward locally manufactured, high-specification anchoring systems is enhancing regional self-reliance while reducing project costs and lead times.

Key Growth Drivers and Market Trends

- Infrastructure Investment and Urbanization – Expanding megacities and rehabilitation of aging transport networks are spurring long-term demand for reliable structural fastening solutions.

- Fast-Curing Technology Leadership – The dominance of fast-curing epoxy anchors highlights growing emphasis on shorter installation times, improved bonding strength, and reduced downtime.

- Sustainability and Green Construction – Increasing adoption of low-VOC, non-toxic epoxy resins is aligning product innovation with environmental goals.

- Automation in Installation – Advancements in automated dispensing tools and robotic precision anchoring are enhancing consistency and safety on large job sites.

- Seismic Retrofitting Demand – Regions with high seismic activity, notably Japan, the U.S. West Coast, and Southern Europe, are integrating high-strength epoxy anchors into mandatory safety standards.

Gain complete access to the report for extensive coverage of market forecasts, competitive benchmarking, and evolving industry trends! Buy Full Report: https://www.futuremarketinsights.com/checkout/27972

Challenges Ahead

Despite steady momentum, the market faces several headwinds. Volatile raw-material prices, particularly for resins and steel, can compress margins. Skilled labor shortages in emerging economies continue to impede proper installation and quality assurance. Moreover, evolving regulatory frameworks governing chemical handling and emissions require manufacturers to innovate continuously to maintain compliance and competitiveness.

Nevertheless, companies that proactively adapt — through research, training, and digitalization — are poised to outperform competitors and capture a greater share of the high-value segment.

Strategic Outlook

By 2035, injection epoxy chemical anchors will be an indispensable component of the global construction and industrial fastening ecosystem. The market’s growth trajectory underscores a structural transformation driven by technology, safety, and sustainability.

- In APAC, local production capacity and rapid project rollout will sustain momentum.

- In Europe, green chemistry and retrofit projects will define the next growth phase.

- In the United States, infrastructure revitalization will remain the primary driver.

- In Saudi Arabia, visionary mega-developments will anchor long-term expansion.

Together, these four markets will account for the majority of incremental global demand, cementing their roles as critical centers of innovation and investment.

Future Opportunities

The decade ahead offers an expansive horizon for both established and emerging manufacturers. Investment priorities include:

- Developing hybrid epoxy formulations with superior bonding on composite and lightweight substrates.

- Expanding digital monitoring systems to ensure real-time quality verification during installation.

- Building regional production hubs to minimize logistics costs and support faster delivery.

Strengthening training partnerships with construction firms to enhance skilled workforce availability.

Early movers who align with these opportunities will be well-positioned to capitalize on the market’s evolution and capture significant value across every stage of the supply chain.

Exploring Insights Across Emerging Global Markets:

Wood Coatings Market: https://www.futuremarketinsights.com/reports/global-wood-coatings-market

Ortho-Xylene Market: https://www.futuremarketinsights.com/reports/global-ortho-xylene-market

Conductive Polymer Coatings Market: https://www.futuremarketinsights.com/reports/global-conductive-polymer-coatings-market

Lead Market: https://www.futuremarketinsights.com/reports/global-lead-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why Choose FMI: Empowering Decisions that Drive Real-World Outcomes: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+18455795705 ext.

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.